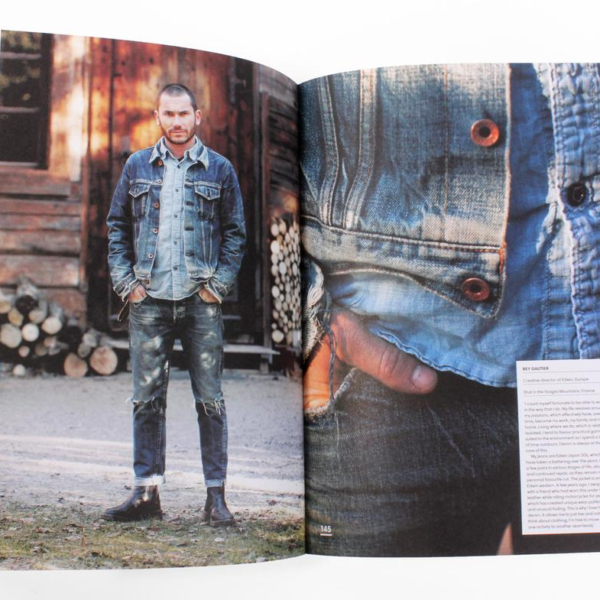

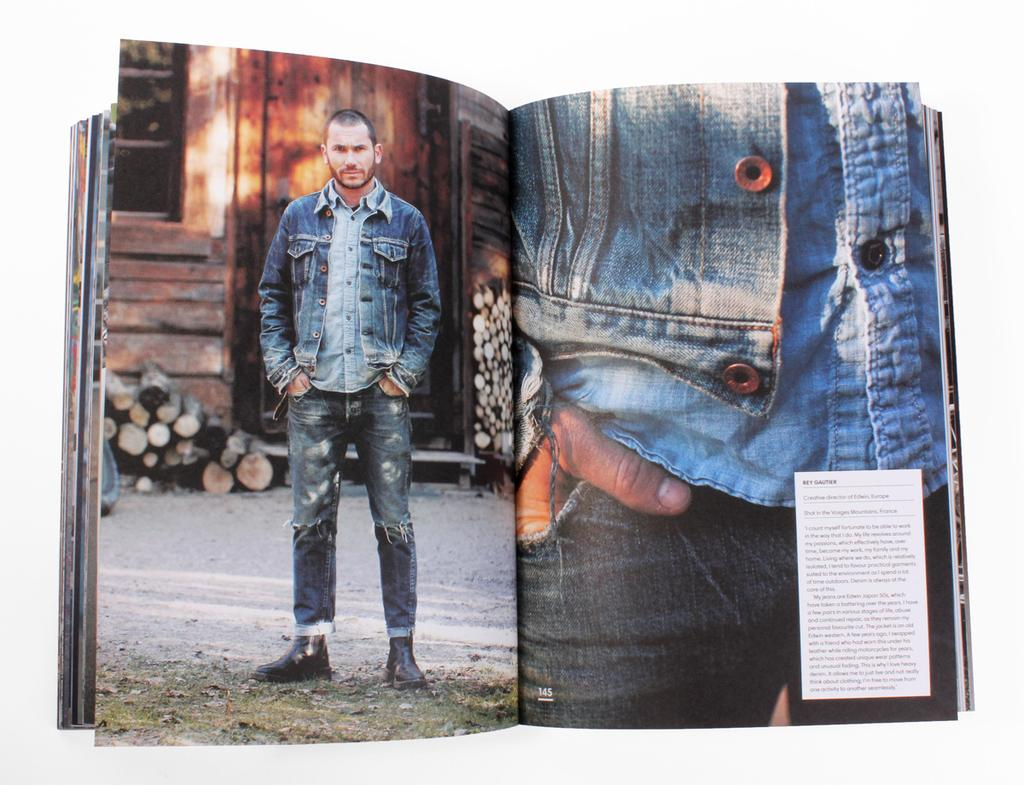

- Rey Gautier, Creative Director of Edwin, Europe (photo by Sam Christmas)

- Olu Alege, Co-Founder of www.streetlevelculture.com (photo by Marta Thisner)

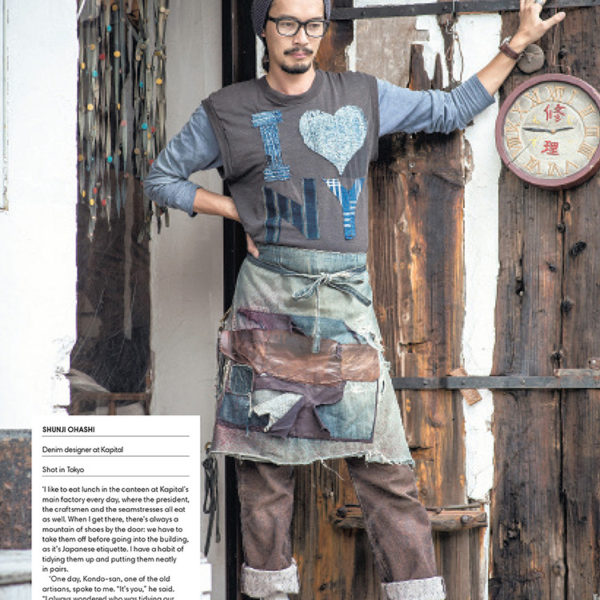

- Shunji Ohashi, Denim Designer at Kapital (photo by Takuya Shima)

- Menno Van Meurs, Co-Founder of Tenue de Nimes and Miles Johnson, Head of Levi’s Vintage Clothing (both photos by Kelly Fober)

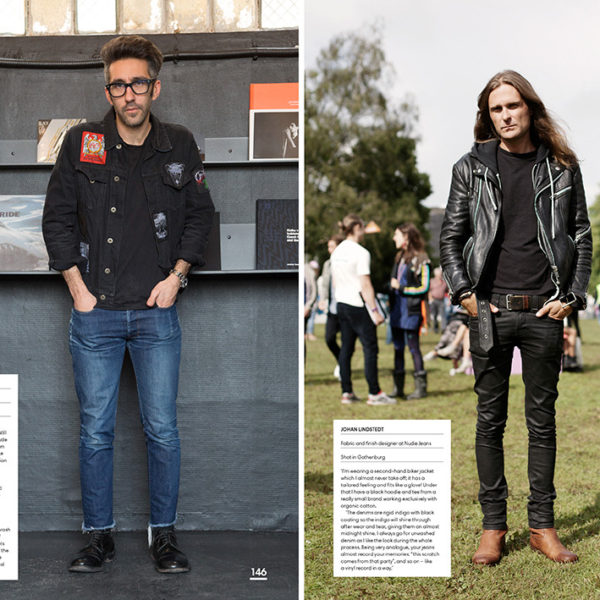

- Brice Partouche, Founder of April77 (photo by Valentina Frugiuele) and Johan Lindstedt, Designer at Nudie Jeans (photo by Marta Thisner)

- Doug Gunn, Co-Founder of The Vintage Showroom (photo by Stephanie Sian-Smith)

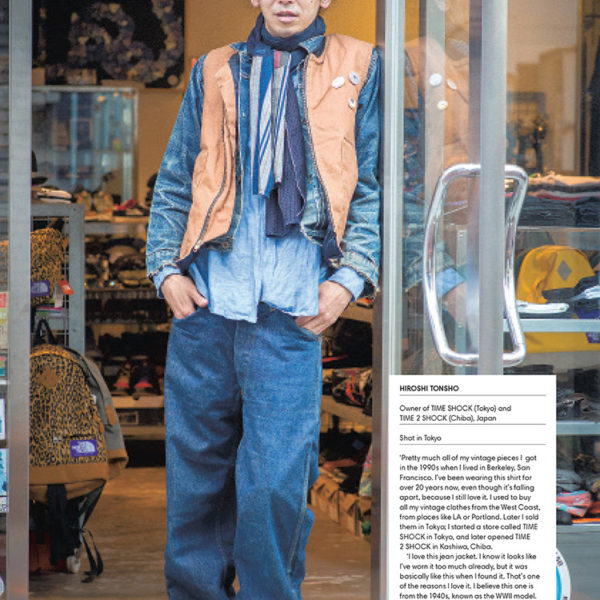

- Hiroshi Tonsho, Owner of Time Shock (photo by Takuya Shima)

- Close up photos by Albert Comper and Stephanie Sian-Smith

- Close up photos by Albert Comper

- Axel Nyhage, CEO of The Local Firm (photo by Marta Thisner) and Ryuichi Adachi, Designer at Big John (photo by Takuya Shima)

For those who can’t enough of vintage workwear and faded denim, Amy Leverton has a new book coming out this March through Laurence King Publishing. Titled Denim Dudes, it’s a street-style book (loosely speaking, anyway) that focuses on key players in the denim community. With over seventy-five men featured from around the world, you can think of this as a sort of stylish “who’s who” directory for the denim scene.

Most of the book features the kind of looks you’d expect – beat-up jeans with chambray shirts and work jackets – but there’s also an appreciable level of diversity. Nudie designer Johan Lindstedt and April77 founder Brice Partouche can be seen above wearing a more rock-and-roll look (black jackets with plain hem jeans), while the head of Levi’s Vintage Clothing, Miles Johnson, is shown wearing something a little more eccentric. (Johnson’s jeans are an original pair of Levi’s 501s from the 1950s, which he found brand new and unworn. He gave them a friend who works in a plastics factory, who then returned them after a year, beaten-up and worn-in. Johnson removed the spots of paint and plastic with some solvents and sandpaper, which is what gives them their look now).

My favorite photos might be from the chapter on Japan – the country that started this vintage workwear revival. Here, you’ll see Kapital’s designer, Shunji Ohashi, wearing a patched-up apron he received from a worker at Kapital’s main factory. There are also some nice photos of Time Shock’s owner Hiroshi Tonsho, shown above wearing a boro scarf with some vintage clothes he’s picked up over the years. Both men exhibit the kind of wabi sabi look we’ve written about in the past.

Like with most fashion books, I wish there was more to read – especially since Leverton was able to get a hold of such key players – but as a source of style inspiration, Denim Dudes is a nice title (at the current pre-order price on Amazon, it’s not much more than what Japanese menswear magazines retail for in the US). Granted, the styles are nothing new – and neither are the clothes – but that’s also what makes them great.