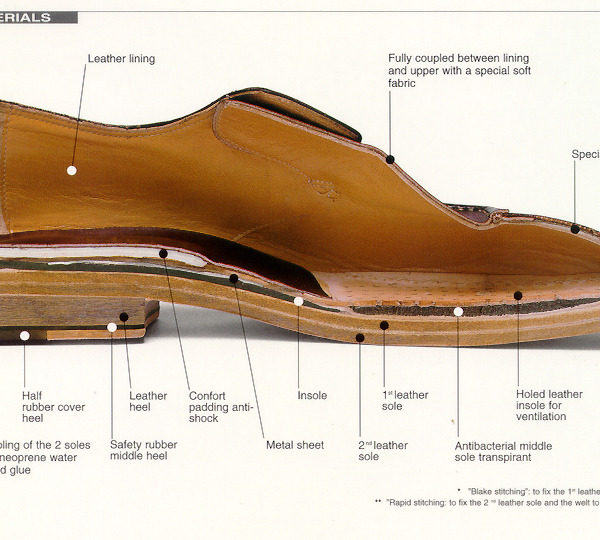

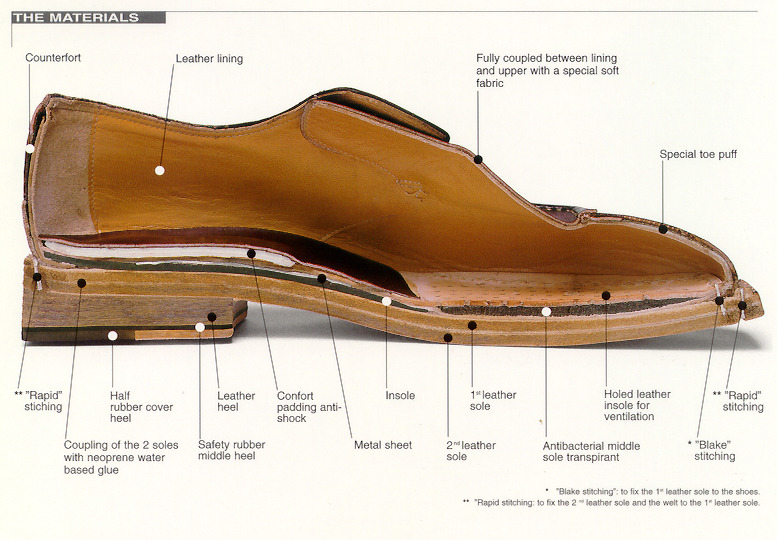

StyleForum member jcusey made a really nice graphic many years ago showing the inside of a Blake/ Rapid stitched shoe. As many readers may know, Blake/ Rapid and Goodyear welt constructions are the two most common methods for making high-end footwear. They’re essentially different ways of attaching the shoe’s sole. Blake/ Rapid is done as you see above – the stitching goes through the sole, insole, and upper in order to attach all three parts together. That’s why when you look inside a Blake stitched shoe, you can usually see the stitching go around the perimeter of the insole (the part of the shoe your feet actually comes in contact with).

Goodyear differs in that there’s no interior stitching. Instead, there’s one line of stitching that goes through the insole, upper, and a welt strip, and then another that attaches the welt strip to the outsole. There’s also a canvas rib just under the insole, which creates a sort of “void” that is taken up by a cork filling. Some people say this canvas rib is prone to breakdowns, but this matter is so controversial among footwear enthusiasts that it’s probably best left alone for now (though, if you really want to learn about it, you can read this forum thread at Ask Andy About Clothes). You can see the inside of a Goodywear welted shoe here.

Of course, none of this information is really useful or practical unless you’re in the shoe trade, but it is fun to know.